FAG tapered roller bearings comprise an outer and inner ring with tapered raceways as well as tapered rollers in a window cage. These are single row individual bearings, usually of open design, which for technical reasons are always adjusted against a second tapered roller bearing in a mirror image arrangement. Open bearings are not self-retaining. As a result, the inner ring with the rollers and the cage can be mounted separately from the outer ring.

FAG tapered roller bearings can support high radial and axial loads in equal measure. Depending on the arrangement, they are suitable when precise axial guidance of the shaft is required (locating bearing function), or when the bearing arrangement must have very high axial rigidity and be operated clearance-free or under preload.

FAG tapered roller bearings are available as:

- single row tapered roller bearings of standard design

- matched tapered roller bearings (fitted in pairs in X, O or tandem arrangement, open design)

- integral tapered roller bearings (fitted in pairs, sealed on one side, not separable).

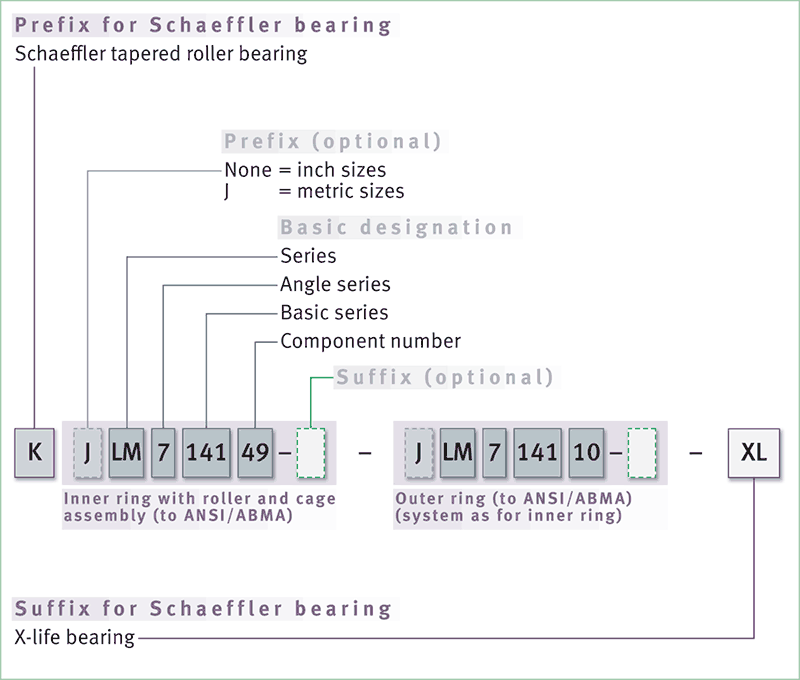

FAG tapered roller bearings are produced in metric and inch sizes.

Classification and designation - bearings in metric and inch sizes

FAG tapered roller bearings in metric sizes:

- DIN 720 : 2008

- ISO 355 : 2007

- ANSI/ABMA 19 . 1 : 2011 (prefix KJ)

FAG tapered roller bearings in inch sizes:

- ANSI/ABMA 19 . 2 : 2013 (prefix K)

FAG tapered roller bearings of basic design

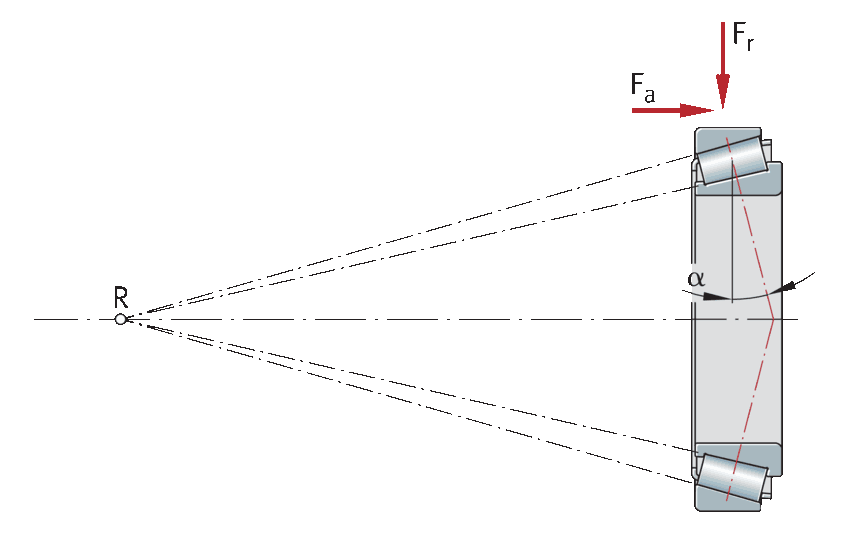

FAG Tapered roller bearings are part of the group of radial roller bearings. In contrast to the ball, the roller has a larger contact area perpendicular to the roller axis. As a result, it can transmit higher forces, has greater rigidity and allows smaller rolling elements under the same load. The single row and multi-row bearings comprise a ribless outer ring, an inner ring with two ribs of different heights and a cage. The cage contains truncated conical rollers. The roller and cage assembly together with the inner ring forms a unit. The low rib retains, in conjunction with the cage, the rollers on the inner ring raceway; the high rib supports the axial force component arising from the tapered form of the rollers. While the tapered rollers roll on the raceways, they slide on the higher rib of the inner ring. The projected lines of contact of the tapered rollers intersect the projected raceways of the inner and outer ring at a point on the bearing axis. As a result of this geometrical characteristic, tapered roller bearings are highly suitable for supporting combined loads. This also prevents any kinematic forced slippage at the rolling contact.

The high dimensional and geometrical accuracy of the rollers reduces running noise and vibrations

Due to the dimensional and geometrical accuracy of the tapered rollers, the rolling elements in a roller set are subjected to virtually the same proportion of load in the load range. In operation, this leads to low-noise and low-vibration running, as well as a high adjustment accuracy.

Single row tapered roller bearing: the apex points of the tapered surfaces meet at a point on the bearing axis

Fr = radial load

Fa = axial load

R = roller cone apex

α = nominal contact angle

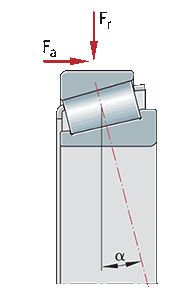

FAG single row tapered roller bearings

FAG single row tapered roller bearings are individual, single row bearings of open design which, for technical reasons, are always adjusted against a second tapered roller bearing in a mirror image arrangement. The FAG bearings are designed such that they reliably cover the extensive demands in relation to generally common requirements. For example, in order to improve the lubricant film formation and running characteristics, the sliding surfaces on the guidance rib of the inner ring, as well as the end faces and contact profile of the rollers, have been optimised. In addition, the high production accuracy allows the bearings to be adjusted against each other with high functional security. This in turn leads to improved operating characteristics and thus to a higher operational reliability. Tapered roller bearings are not self-retaining. As a result, the inner ring with the roller and cage assembly can be mounted separately from the outer ring. This gives simplified mounting of the bearings.

Fa = axial load

α = nominal contact angle

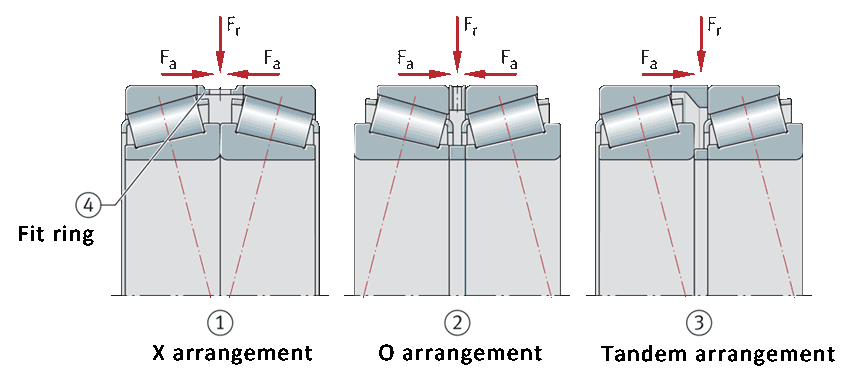

FAG matched tapered roller bearings

If the load carrying capacity of a bearing is not sufficient or the shaft is to be guided in both directions with a specific axial clearance, then ready-to-fit, matched bearing sets are available. Matched tapered roller bearings are essentially available in three arrangements comprising an X, O and tandem arrangement.

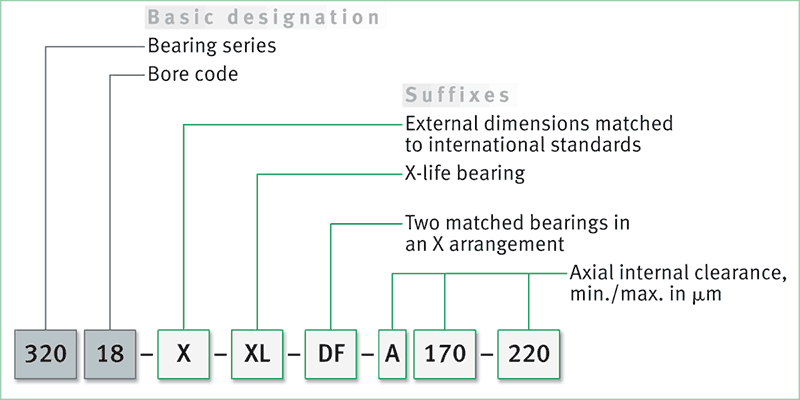

X arrangement

For bearing sets in an X arrangement, the contact lines converge relative to the bearing axis. Axial forces occur from both directions, but are always only supported by one bearing. The X arrangement is of simple design and the most frequently used arrangement of matched tapered roller bearings fitted in pairs.

O arrangement

For bearing sets in an O arrangement, the contact lines diverge relative to the bearing axis. Axial forces occur from both directions, but are always only supported by one bearing. The support base is at its largest in the O arrangement, which is beneficial if the component with small bearing spacing must be guided with the smallest possible tilting clearance, or tilting forces must be supported. Bearing arrangements in an O arrangement are relatively rigid and can also support loads resulting from tilting moments.

Tandem arrangement

For bearing sets in a tandem arrangement, the contact lines run parallel to each other. In contrast to an X and O arrangement, the tandem arrangement can only support axial force in one direction. This bearing pair is usually adjusted against another tapered roller bearing, which supports axial forces in the opposite direction.

How to order FAG matched tapered roller bearing

In order to simplify the ordering process, the ordering designation is modified for matched tapered roller bearings fitted in pairs:

- The first module letter D = 2 (duplex) represents the number of bearings

- The second module letter represents the bearing arrangement:

- B = O arrangement - Back to Back

- F = X arrangement - Face to Face

- T = tandem arrangement

- Where necessary (special design), a third module letter is added as a continuous counter for describing a variant. Example: A, B, … = different set width, variant of intermediate ring design

- The axial internal clearance is indicated explicitly in the designation. For example, A80-120 means that the axial internal clearance of the unmounted bearing pair (delivered condition) is between 80 μm and 120 μm.

Please note that the number of bearing pairs must be stated when ordering matched tapered roller bearings.

FAG integral tapered roller bearings (JK0S) - fitted in pairs

Integral tapered roller bearings are ready-to-fit bearing units, which are greased, sealed on one side and predominantly mounted in pairs in an O arrangement. The FAG bearings are not separable.

The precise axial internal clearance is not achieved by adjusting the bearings, but is set automatically when the recommended bearing seat tolerances are observed. As a result, there is no need to adjust the bearings against each other in the manner normally required. When integral tapered roller bearings are mounted in pairs, a slot is formed on the outer ring for the retaining ring (snap ring BR). Schaeffler integral tapered roller bearings are interchangeable with each other.

When ordering, please always state the number of individual bearings and not the number of bearing pairs. The snap ring must be ordered separately, for example:

- 2 tapered roller bearings JK0S080-A

- 1 snap ring BR125

Dimensions, tolerances

The main dimensions of bearings in metric sizes correspond to ISO 355:2007 and DIN 720:2008. Bearings in metric sizes with the prefix KJ correspond to ANSI/ABMA 19.1:2011.

Chamfer dimensions

Tapered roller bearings in metric sizes

The limiting dimensions for the chamfer dimensions of metric tapered roller bearings to DIN/ISO correspond to ISO 582:1995. Overview and limiting values for metric tapered roller bearings to DIN/ISO. please refer to Chamfer dimensions

Bearings in inch sizes to ANSI/ABMA

Minimum chamfer dimensions rmin for bearings in inch sizes correspond to ANSI/ABMA 19.2:2013.

Tolerances

All tapered roller bearings to DIN 720, ISO 355 and integral tapered roller bearings have the tolerance class Normal to ISO 492:2014. In contrast to the standard, X-life bearings achieve improved radial runout values tKia and tKea, in addition to dedicated axial runout values tSia.

please refer to Bearing tolerance chart, table for more details.

Suffixes

For a description of the suffixes used in this chapter. Regarding more suffixes of FAG bearigs, please refer to Schaeffler bearing suffix, prefix, FAG, INA

Suffixes and corresponding descriptions

| Suffix | Description of suffix |

|---|---|

| A | Modified internal construction (excluding bearings to ANSI/ABMA) |

| B | Increased contact angle (for bearings to DIN) |

| DF-A..-.. | Two tapered roller bearings matched in an X arrangement, with an intermediate ring between the outer rings. Axial internal clearance between .. and .. in μm |

| X | External dimensions matched to international standards (for bearings to DIN) |

| XL | X-life |

Tapered roller bearings for special applications

Special tapered roller bearings are available for applications where tapered roller bearing arrangements are used under very difficult operating conditions.

Special designs, available by agreement

| Suffix | Description of suffix |

|---|---|

| DB-A..-.. | Two tapered roller bearings matched in an O arrangement, with an intermediate ring between the outer rings and the inner rings, axial internal clearance between .. and .. in μm |

| DT | Two tapered roller bearings matched in a tandem arrangement, with an intermediate ring between the outer rings |

| P5 | Bearing in tolerance class 5 |

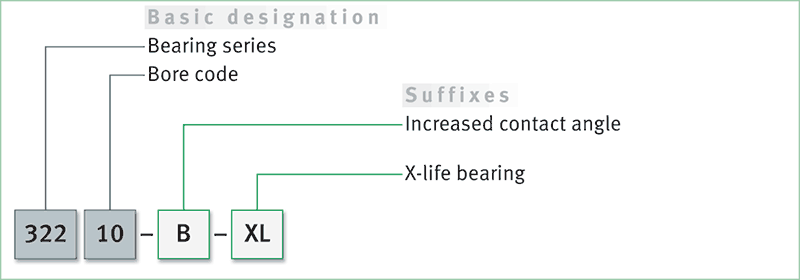

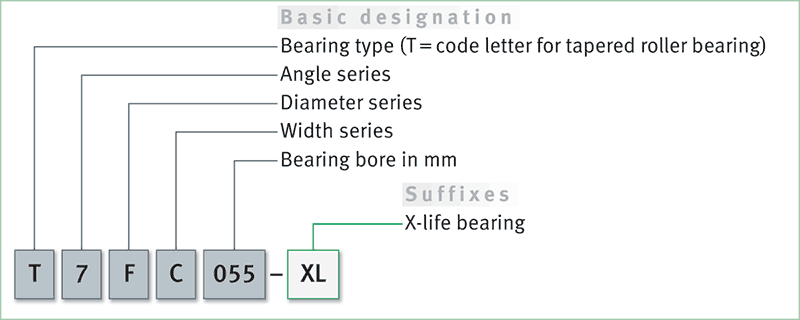

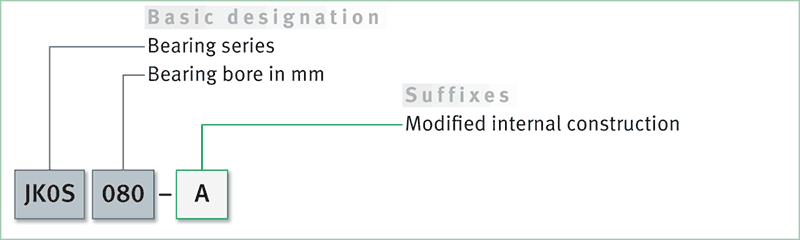

Structure of FAG tapered roller bearing designation

Each FAG roller bearing has a designation which clearly indicates the type, dimensions, tolerances and internal clearance, if necessary with other important features. please refer to FAG bearings nomenclature, designation system

Examples of composition of bearing designation