KAYDON thin section ball bearings have a radial cross section that is much thinner than standard dimensioned bearings of the same diameter and are therefore more sensitive to shaft and housing fits.

Correct mounting is essential so that the bearing functions as intended. There are a number of factors to consider when mounting a KAYDON thin section bearing, including:

- bearing type and orientation

- the direction and magnitude of the applied loads

- permissible clearance in the bearing

- the maximum permissible torque

- shaft and housing materials

- operating temperature

- which ring is rotating

Mounting should be undertaken in a clean environment, which is vital to bearing performance.

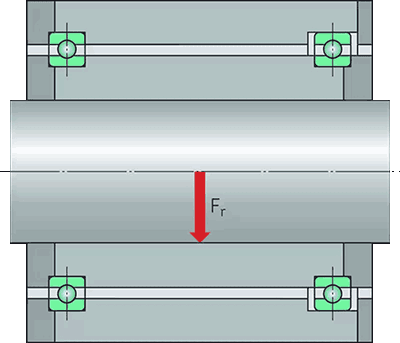

Mounting for KAYDON radial contact ball bearings (type C)

KAYDON radial contact ball bearings are typically used when the applied loads are predominantly in the radial direction.

If two KAYDON bearings are used on opposite ends of a long shaft, then one of the bearings should be allowed to move freely in the axial direction. This is done so that thermal expansion of the shaft or housing does not induce an axial load into the radial bearing.

The recommended shaft and housing tolerances refer to Tolerances and recommended fits for Kaydon thin section bearings. Generally, a light interference fit between the bearing and either the shaft or housing, whichever is rotating, is recommended. A slight amount of clearance is recommended for the non-rotating (stationary) ring.

Most radial ball bearings are supplied with an internal radial clearance. Using the recommended fits means that the KAYDON bearings will not become radially preloaded after mounting. Preload could affect bearing life and performance.

The recommended fits apply only to bearings with standard clearance, which is also shown in the tolerance tables. They also apply only to steel shafts and housings, or ambient temperature applications. If dissimilar metals are used, then the fits will change with temperature. This could cause the bearing to become radially preloaded, leading to an excessive frictional moment. When bearings are supplied with a radial preload, a slight clearance is recommended for both the shaft and housing.

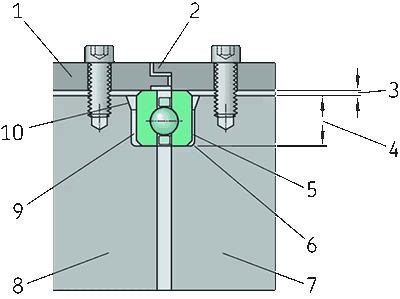

Face clamps to hold the bearing in place: 1 Face clamps, 2 Labyrinth shield, 3 Gap, 4 Seat depth, 5 Interference fit, 6 Small fillets on shoulders (bearing seats), 7 Shaft, 8 Housing, 9 Loose fit, 10 Lead-in chamfer

Face clamps are recommended for use with all bearings. The user should not rely solely on an interference fit to hold the bearing in place.

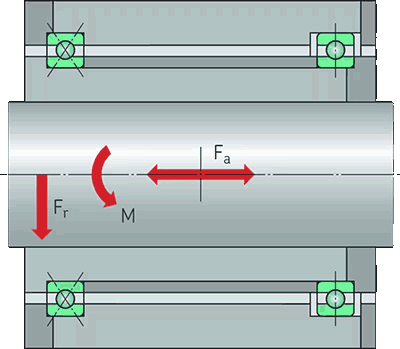

Mounting for KAYDON four-point contact ball bearings (type X)

KAYDON four-point contact ball bearings (type X) are used when there is an axial applied load or some combination of radial, axial and moment loads.

If two KAYDON bearings are used on the opposite ends of a long shaft, the second bearing should be a radial contact ball bearing (type C), and it should be allowed to be displaced axially. Using two four-point contact ball bearings on the same shaft is not recommended.

As with radial ball bearings, these fits apply only to bearings supplied with the standard clearance, and to steel shafts and housings or ambient temperature applications.

KAYDON four-point contact ball bearings can also be supplied with a radial preload. Where these preloaded bearings are used, a slight clearance is recommended for both the shaft and housing.

A single four-point contact ball bearing accommodates an axial load in both directions, and also radial and moment loads. However, this type of KAYDON bearing typically has higher friction than a radial (type C) or an angular contact (type A) ball bearing of the same size. Therefore, for torque-sensitive and high-speed applications, matched sets of angular contact ball bearings are generally used in place of a single four-point contact ball bearing.

Mounting for KAYDON angular contact ball bearings (type A)

KAYDON angular contact ball bearings (type A) can take an axial load in only one direction, and therefore are almost always used in a set of two bearings.

They can be used in either a back-to-back arrangement or a face-to-face arrangement, as described in how to select KAYDON thin section bearing type. Sets of two angular contact ball bearings are normally used with some amount of axial preload to remove all clearance and increase stiffness. KAYDON angular contact ball bearings can be purchased as matched sets where the axial preload is set by the factory, or as individual bearings where the axial preload is set during mounting.

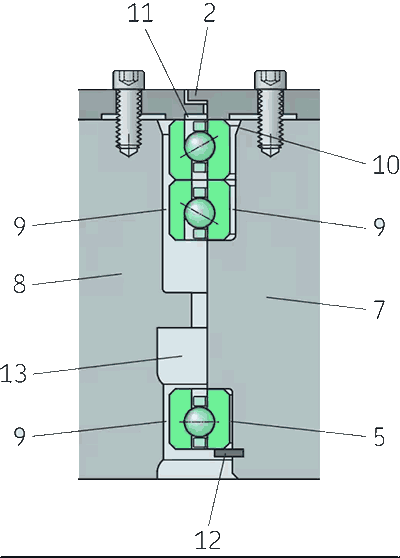

2 Labyrinth shield, 5 Interference fit, 7 Shaft, 8 Housing, 9 Loose fit, 10 Lead-in chamfer, 11 Clearance relief, 12 Double-wound snap ring, 13 Relieved area

When angular contact ball bearings are purchased as a matched set of bearings, the inner and outer rings simply need to be clamped in place.

For KAYDON thin section bearings with an axial preload, there should be a slight clearance between the bearing and both the shaft and housing. If a third bearing is used on the opposite end of a long shaft, it should be either a single radial or a face-to-face set of bearings. It should also be free to be displaced in the axial direction. Using two sets of back-to-back bearings on the same shaft is not recommended.

Back-to-back arrangement

If KAYDON angular contact ball bearings are purchased as individual bearings, the axial preload needs to be set during mounting.

If KAYDON bearings are used in a back-to-back arrangement, the preload is set by pressing the inner rings of the two bearings towards each other. The axial preload is set using shims.

If the axial load is applied in only one direction, then KAYDON bearings can also be preloaded using a wave spring.

For a back-to-back arrangement, a slight interference fit is recommended between the bearing outside diameter and the housing. A loose fit is required between bearing and shaft so the inner rings are free to be displaced in the axial direction.

The recommended shaft and housing tolerances are shown in the tables in the relevant general bearing specifications. These fits are for steel shafts and housings, or for ambient temperature applications. If dissimilar metals are used, then the fits will change with temperature. In this case, looser fits may be advisable to prevent excessive frictional moments at high and low temperatures.

The bearing life and load rating of a set of two KAYDON angular contact ball bearings under an applied moment load can be increased by spacing the bearings further apart. The angular deflection (tilt) of the shaft under an applied moment also decreases as the spacing increases. However, the bearings can become more sensitive to differential thermal expansion if the shaft and housing are different materials or if they operate at different temperatures.

Face-to-face arrangement

In a face-to-face arrangement, the preload is set by pressing the outer rings towards each other. The preload can also be set with shims or wave springs.

For this type of arrangement, a slight interference fit is used between Kaydon bearing bore diameter and the shaft. A slight clearance is required between the bearing outside diameter and the housing. The recommended shaft and housing tolerances are shown in the tables in the relevant general bearing specifications. As with the back-to-back arrangement, if dissimilar metals are used, looser fits may be necessary to prevent excessive frictional moments at high and low temperatures.