Kaydon thin section ball bearings are available in three different bearing types:

- Radial contact ball bearings (type C)

- Angular contact ball bearings (type A)

On request, Kaydon angular contact ball bearings can be supplied as matched bearing sets in three different arrangements:- Tandem arrangement

- Back-to-back arrangement

- Face-to-face arrangement

- Four-point contact ball bearings (type X)

These provide multiple options to meet load, stiffness and accuracy requirements in the most efficient manner.

Kaydon radial contact ball bearings (type C)

Kaydon type C bearings are single row radial contact ball bearings with extra deep ball grooves in both rings (groove depth = 25% of ball diameter).

Conventional design bearings:

- have an eccentric displacement of the inner ring within the outer ring, which permits insertion of about half of a full complement of balls

- have rings positioned concentrically and the balls spaced around the entire circumference for assembly of the cage/separator

Bearings with filling slot(s):

- have a filling slot in one or both rings to accommodate more balls than a conventional bearing design (filling slots are used on several bearing types, including full complement bearings and bearings that have toroid ball spacers, spacer balls and formed wire separators)

- have a higher radial load carrying capacity than bearings without filling slots, but their axial load carrying capacity is limited

- are unable to operate at the same high speeds as bearings without filling slots

If higher axial loads are expected for a specific application, a set of Kaydon angular contact ball bearings (type A) should be considered.

Clearances

Type C bearings perform best with a small amount of clearance between the balls and rings (radial clearance, which may be increased or decreased to meet operating conditions).

As standard, Kaydon bearings are supplied with clearances for:

- interference fits between bearing rings and shafts/housings

- differential thermal expansion or contraction of steel rings

- misalignment between shaft and housing and other factors that may require the clearance to be adjusted accordingly

Kaydon radial contact ball bearings (type C) are designed to have contact between the balls and rings in the plane of the ball centres when only a radial load is applied.

While designed primarily for radial load applications, Kaydon type C bearing without a filling slot can accept some axial load in either direction. The ability to accommodate axial loads depends on the amount of clearance in the bearing after mounting. In the case of bearings with filling slot(s), the slot(s) can possibly truncate the contact ellipse under axial load, reducing the bearing's capability to support axial load.

By increasing the radial clearance beyond the standard amount, the type C bearing can have a greater angle of contact under axial load, and thus greater axial load capability. In this case, it is recommended that the bearing be adjusted against another bearing of similar construction to reduce axial movement under reversing axial loads. Used in this manner, the bearing is essentially an angular contact ball bearing rather than a radial contact ball bearing.

Angular contact ball bearings (type A)

Kaydon type A bearings are angular contact ball bearings with extra deep ball grooves in both rings (groove depth = 25% of ball diameter).

Conventional design bearings:

- have sufficient radial clearance to produce a 30° contact angle (α) to accommodate axial loads

- feature a circular pocket cage with approximately 67% of a full complement of balls

- provide a greater axial load capability than a type C or type X bearing:

- One ring, usually the outer, is counterbored to reduce one shoulder of the raceway so that (with the assistance of a temperature differential between the two rings) the outer ring can be installed over the inner ring, ball and cage.

- Doing this provides a non-separable bearing capable of accommodating greater radial loads while accommodating substantial axial loads in one direction.

- With axial loads applied, the faces of the inner and outer rings are approximately flush, which minimizes preload adjustments.

- should be mounted opposed to another bearing such that an axial load is present to establish and maintain the contact angle, and to accommodate reversing axial loads with minimized axial movement

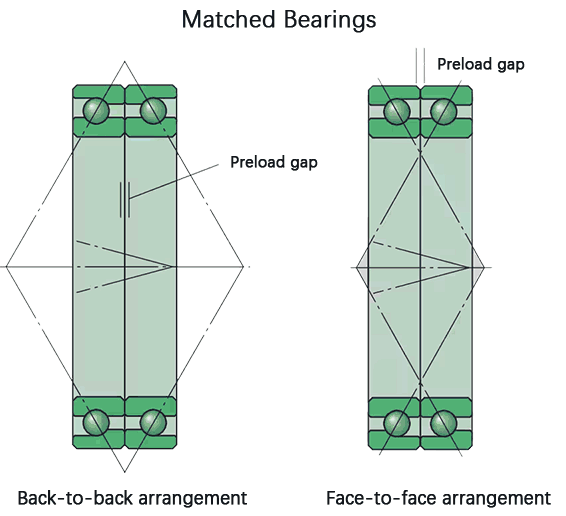

Back-to-back arrangement

Kaydon angular contact ball bearings (type A) can be arranged back-to-back with the load lines diverging from the bearing axis:

- The bearings are adjusted through the inner rings by use of shims between the bearing inner ring and the clamping ring.

- Sufficient shim thickness is provided to allow axial movement of the shaft relative to the housing.

- The total axial movement can then be measured and the shim thickness reduced by the amount of movement plus any additional amount desired for preload.

- When two Kaydon bearings are opposed to each other to the extent that all internal clearance is removed and elastic deformation occurs between the balls and raceways, the bearings are preloaded.

Face-to-face arrangement

Kaydon angular contact ball bearings (type A) can be arranged face-to-face with the load lines converging towards the bearing axis:

- Inner and outer ring spacers are used between both bearings and adjustment of axial clearance or preload is possible by varying the length of one spacer relative to the other.

- Normally, the spacers are equal in length and the bearings are furnished as a matched set with a predetermined axial preload or clearance.

- If the outer ring spacer is removed from this assembly, the bearings can be adjusted by use of shims between the bearing inner ring and the clamping ring.

Matched bearings

Matched sets of two Kaydon type A bearings are mounted adjacent to one another or with equal length inner and outer ring spacers. When required, assemblies with matched ground spacers can be supplied.

Sets of three, four or more bearings can also be matched where conditions require additional load capability and there is insufficient space radially for larger bearings:

- Sets are matched within close limits for the size of bore and outside diameter.

- Each set is marked with a "V" across the bores and outside diameters at the high point of radial run-out and indicate how to assemble the bearings properly when mounting.

The sets of bearings shown as follow are normally furnished with the ring faces precision ground to provide preload when mounted. To accomplish this:

- A gap is provided between the inner rings and between the outer rings of the bearings.

- When Kaydon bearings are mounted and clamped axially, the gap is closed, producing a preload on the bearings.

Back-to-back arrangements:

- provide greater stiffness under moment loading

- should be used when the space between single bearings is small or when a single set of adjacent bearings is employed

Face-to-face arrangements:

- are less sensitive to angular misalignment between the shaft and housing

- should be considered when there are multiple sets of two bearings along an axis

Single bearings arranged face-to-face must be spaced sufficiently to accommodate moment loads. If required, a face-to-face set of two bearings can be mounted in conjunction with another bearing in a locating/non-locating arrangement with the set in the locating position.

Tandem arrangements:

- can accommodate axial loads in one direction only

- must be mounted opposed to another bearing or set

The values for load ratings listed in the product tables apply to single bearings. For matched sets, the following applies:

Cset = N0.7Csingle

Cset: load rating for a bearing set [kN]

Csingle: load rating for a single bearing [kN]

N: number of bearings in the set

For the axial load rating in each direction, N identifies the number of bearings accommodating axial loads in that specific direction.

Unless specifically requested, the outboard faces of bearing sets are not controlled. If the outer face flushness is required for preload purposes, bearings ground for universal matching should be considered. With these sets, both inner and outer faces are matched under a specified gauge load to control preload and allow for mounting orientation flexibility.

Four-point contact ball bearings (type X)

Kaydon type X bearings are distinguishable from types A and C by the geometry of their raceway grooves:

- type C: centres of the radii both lie in the plane of the ball centres

- type A: with the rings and balls in angular contact, the centres of the groove radii are offset by equal amounts on either side of the plane of the ball centres

- type X: the groove in each ring has two radii whose centres are offset from the plane of the ball centres

Kaydon type X bearings are assembled by the two methods described under type C bearings: either conventional design or with filling slots. With a filling slot, both the basic dynamic radial and axial load capabilities are limited by the possible truncation of the contact ellipse at the filling slot and therefore the rotational speed must be limited.

The depth of the groove in the type X bearing is the same as in types A and C (25% of ball diameter).

The specific feature of the "gothic arch" geometry of the inner and outer rings of the type X four-point contact ball bearing, making possible four contact points between a ball and the raceways, which when combined with the deep groove:

- enables a single bearing to carry three types of loading (radial, axial and moment) simultaneously (whereas standard dimensioned bearings are most often designed to accommodate only radial and axial loads)

- makes it an ideal bearing for many applications since a single four-point contact ball bearing can often replace two bearings, such as a set of two type A bearings arranged back-to-back, providing a simplified design

Kaydon type X bearings are designed to be used singly. The use of two type X bearings on a common shaft is not recommended, as it could result in an unacceptable frictional moment.