The lubricant in a Kaydon thin section bearing serves to:

- reduce friction and wear between moving parts

- dissipate heat

- prevent corrosion of critical surfaces

The selection of proper lubricants should be based on an evaluation by the system design engineer of the operating conditions, including as a minimum:

- rotational speed

- type and magnitude of loads

- ambient temperature

The three types of lubricant commonly used are oil, grease, and dry film or surface treatment:

- Oil normally provides more complete lubrication:

- Because of its liquid state, it provides better coverage of the critical surfaces and assists in dissipating heat more readily, the latter being especially true when circulation and cooling are provided.

- In high-speed applications where the heating effect is more pronounced, oil is specified.

- Where minimum torque is a requirement, oil will usually provide lower friction values.

- Grease offers certain advantages of its own:

- Because it is more easily retained, the design of bearing housings and seals is simplified.

- In many applications, the lubricant itself serves to exclude contaminants when used in conjunction with labyrinths or close clearances between the rotating and stationary structures.

- For the higher speeds within the range suitable for grease lubrication, a channelling type of grease is often selected.

- Dry films and surface treatments:

- These have been used as bearing lubricants in applications subject to environmental extremes, particularly where conventional lubricants cannot be tolerated or will not survive.

- A wide variety of types are available for selection - options include tungsten disulfide, graphite, and molybdenum disulfide.

The effect of lubricant on Kaydon bearing performance

It is important to note that the quantity of lubricant affects Kaydon bearing performance under certain operating conditions.

Only relatively small amounts of lubricant are necessary to reduce friction and wear if a film can be maintained on all contacting surfaces. Where speed is significant, excessive amounts of oil or grease will result in higher operating temperatures, leading to the possibility of early bearing fatigue.

Depending on the bearing design and application, typical grease fill volumes vary from 10 to 30% of the free space in Kaydon bearing.

Specifying greases and oils

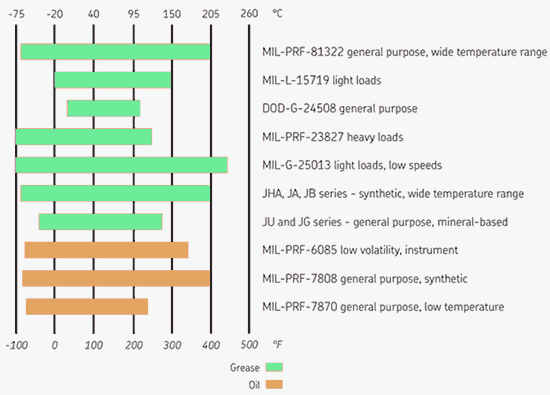

Kaydon bearings with or without seals can be supplied with optional lubricants. Some of the greases and oils frequently specified are shown in picture below. Several have been developed to meet the requirements of unusual operating conditions. Because of this and the variation in cost, it is recommended that lubricants be selected with the assistance of a lubrication expert.

Note: Due to the finite shelf life of any wet lubricant, factory-lubricated bearings should not be stored for more than three years prior to use.

To realize the full potential of a Kaydon thin section bearing, maintenance instructions and schedules should consider the operating conditions and include procedures so that the bearings are adequately protected against the intrusion of foreign matter of all types, and that fresh oil or grease is introduced with sufficient frequency to cleanse the bearing and provide adequate lubrication.