To realize the full benefits from Kaydon thin section bearings, it is important to keep them clean and well lubricated. Seals and shields, properly designed and installed, help to accomplish this.

Integral sealing

Seal - a contacting closure between the stationary and rotating rings, for keeping lubricant in and contaminants out of the bearing. Seals are fitted in the outer ring and make positive contact with the inner ring.

Shield - a closure for the same purpose as a seal but without positive contact.

A seal is more effective, but requires more turning effort (torque), generates more heat and, as a result, has a lower limiting speed than an open or shielded bearing.

The following are examples by which Kaydon Reali-Slim thin section ball bearings may be capped (with seals or shields), either integrally or externally. The lubricant and lubrication systems, torque requirements, rotational speed and operating environment will influence the choice:

- JA, JB and JG series double-sealed Kaydon Reali-Slim bearings - bearing width is the same as that of an open bearing

- JU series double-sealed Reali-Slim bearings - adding shields and seals requires an increase in the width of the bearing

Double-shielded bearing can be used where a shield will suffice or is required due to torque limitations or speed.

Where weight and space are at a premium, and a seal or shield is required on one side only, single-sealed or single-shielded bearings are available as customized options.

Capped Reali-Slim ball bearings are pre-lubricated with a general purpose grease. Operating conditions (i.e. time in operation, temperature, speed, environment) may result in premature lubrication degradation. A variety of lubricants are available as options to meet the required specifications. Integral seals and shields offer a compact overall design.

External sealing

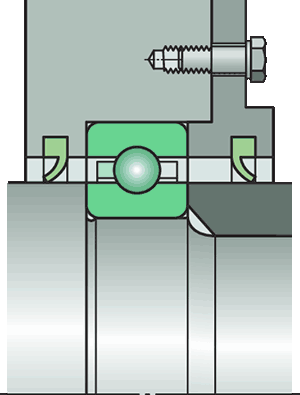

The picture shows a nitrile lip-type seal ring available in a variety of cross sections compatible with the Reali-Slim ball bearing series. Please note that torque is substantial and speeds should not exceed 5.08 m/s (1 000 ft/min) if continuous.

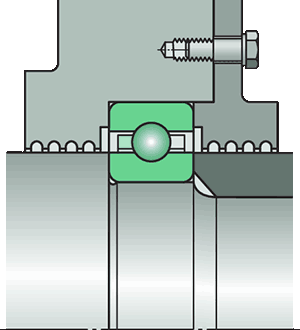

If grease lubrication is used and torque is not critical, an effective gap-type seal is shown in picture below, where annular grooves are cut in the housing shoulder and clamp plate, and filled with grease.

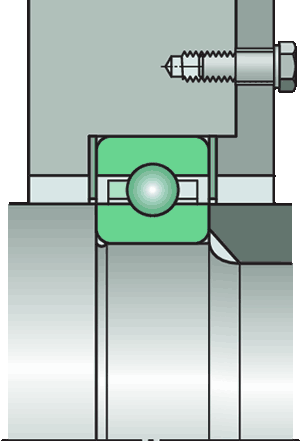

When a separate shield is required, washers made from precision flat stock are ideal, as shown in picture below. They serve well where weight limitations are strict.

Integral seals and shields offer a very compact overall design.