NSK offers a wide lineup of super precision angular contact ball bearings to provide optimal specifications for your application. NSK can supply this type of bearings with a variety of design features:

- NSK's standard super precision angular contact ball bearings conform to ISO standards.

- Ultra high speed angular contact ball bearings

- NSK ROBUST series

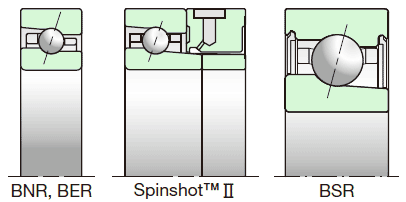

- NSKROBUST SpinshotTM II

- NSKROBUSTTM BSR Series

Numbering system for NSK super precision angular contact ball bearings

| Bearing type (1) | Dimension series(2) | Bore number (3) | Contact angle (4) | Material (8) | Cage (9) | Seal (11) | Arrangement (12) | Preload (13) | Accuracy (14) | Grease brand (16) | Grease quantity (17) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 | 0 | 10 | C | SN24 | TR | V1V | DB | EL | P4 | MTE | X |

| Nominal bore diameter (5) | Bearing type (6) | Dimension series (7) | Material (8) | Cage (9) | Lubrication holes (10) | Seal (11) | Arrangement (12) | Preload (13) | Accuracy (14) | Accessories (15) | Grease brand (16) | Grease quantity (17) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | BNR | 10 | H | TSR | E34 | V1V | DB | EL | P4 | +Y3 | MTE | X |

Bearing type (1, 6)

(1) 7: High accuracy angular contact ball bearings (Standard series)

The high performance standard NSKHPS series features a high basic dynamic load rating and is suitable for low to medium speed operation and high-load applications. NSK's original material evaluation technology ensures only high purity materials are used in their manufacture, which has the most influence on bearing life. Superior steel materials have led to a 15%extension of rolling life.

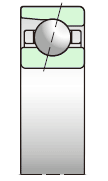

BNR, BER, BSR: high speed angular contact ball bearings (NSKROBUST series)

- BNR: 18° contact angle

- BER: 25° contact angle

- BSR: 15° contact angle

| BNR, BER | BSR | |

|---|---|---|

| 19 Series | 30BxR19 ~ 200BxR19 | 10BSR19 ~ 25BSR19 |

| 10 Series | 30BxR10 ~ 160BxR10 | 6BSR10 ~ 25BSR10 |

| 02 Series | - | 10BSR02 ~ 25BSR02 |

High performance angular contact ball bearings with high rigidity and low heat generation. The results of temperature rise simulations undertaken to evaluate rolling element slip were used to optimize the design of this series.

NSKROBUST bearings are available as S, E, H or X type with different combinations of materials such as high accuracy ceramic balls and heat-resistant high speed SHX steel, enabling our customers to choose the most suitable NSK bearing for each application.

Sealed bearings are available mainly up to 120mm bore diameter. Optimization of the space between seal and cage and minimization of the seal labyrinth prevent grease leakage. The wide-width series (29, 20 series) has been designed to allow more grease to be held inside the bearing. This helps keep temperature rise down and prolongs grease life.

The Spinshot type has been designed for noise reduction and greater reliability of oil-air lubrication during ultra high speed operation.

The BSR series bearings retain high radial rigidity even in high speed operation with constant pressure preload. This makes them ideal for grinders and similar applications.

Dimension series (2,7)

Standard Series (2)

- 9: 19 series

- 0: 10 series

- 2: 02 series

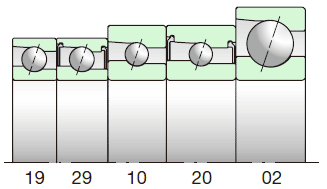

NSKROBUST Series (7)

- 19: 19 series

- 29: 19 series

- 10: 10 series

- 20: 20 series

- 02: 02 series

For identical bore diameters, the bearings' outside diameter and width increase in the order 19-29-10-20-02 series as expressed by the dimension series codes. Please refer to NSK bearing nomenclature

Please note the 29 and 20 series are only available as NSKROBUST series sealed ultra high speed angular contact ball bearings.

Bore Number (3) / Nominal Bore Diameter (5)

Standard Series

Up to 3:

- 00: 10mm

- 01: 12mm

- 02: 15mm

- 03: 17mm

4 and above: Bore diameter = bore number x 5 (mm) (Please refer to Bearing number designation for more details.)

NSKROBUST Series

Nominal bore diameter = Bore dimension (mm)

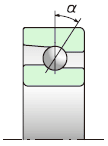

Contact angle (4,6)

Standard Series

- C: 15°

- A5: 25°

- A: 30°

NSKROBUST series

- BNR: 18°

- BER: 25°

- BSR: 15°

Material (8)

Standard series

- No symbol: steel ball

- SN24: ceramic ball

NSKROBUST series

| Type | Material | |

|---|---|---|

| Inner and outer ring | Balls | |

| S | Bearing steel (SUJ2) | Bearing steel (SUJ2) |

| E | Bearing steel (SUJ2) | Ultra long life rolling elements (EQTF) |

| H | Bearing steel (SUJ2) | Ceramic (Si3N4) |

| X | Heat resistant steel for high speed operation (SHX) | Ceramic (Si3N4) |

| XE | Heat resistant steel for high speed operation (SHX) | Ceramic (Si3N4) |

Cage (9)

| Symbol | Material | Guiding | Features | Limiting speed dmn value | Available for |

|---|---|---|---|---|---|

| TYN | Polyamide resin | Ball guided | Excellent wear and noise characteristics, expecially effective with grease lubrication | Oil: 1.4 million Grease: 1.2 million | Standard series NSKROBUST series (not available for 19 series sealed type) |

| T | Phenolic resin | Outer ring guided | Stable cage rotation in high speed operation | 2.8 million | TR: Standard series T: NSKROBUST series TA: BSR series (sealed type) |

| TSR | PPS resin | Outer ring guided | Reduction of non-repeatable run-out (NRRO). Low temperature rise in ultra high speed operation due to unique design with enhanced oil drain | 3.0 million | NSKROBUST series |

| MY | Brass | Ball guided | Excellent noise and temperature rise characteristics. Extended grease life. | Oil: 0.8 million Grease: 0.7 million | Standard series NSKROBUST series (only for large bearing that are not equipped with TYN cages) |

Lubrication holies (10)

No symbol: No lubrication holes

E34: Direc lubricating bearing

E34: Direc lubricating bearing

Space-saving bearings designed specifically for oil-air lubrication, equipped with lubrication groove, lubrication holes and O-ring groove on outer ring.

Available for NSKROBUST series only.

Seal (11)

No symbol: Open type

V1V: Non-contact rubber seal Non-contact rubber seals on both sides of the NSK bearing prevent entry of foreign matter and grease expulsion, thereby ensuring high reliability and longer grease life.

Non-contact rubber seals on both sides of the NSK bearing prevent entry of foreign matter and grease expulsion, thereby ensuring high reliability and longer grease life.

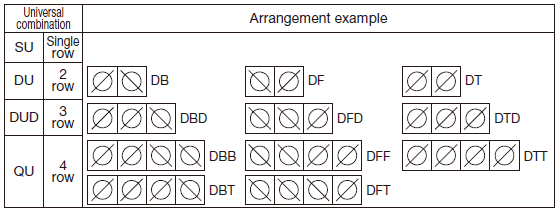

Arrangement (12)

Universal combination NSK bearings SU, DU, DUD, and QU are controlled during production to ensure front face stand out is the same as back face stand out.

In addition, if the NSK bearing number indicates two or more rows (DU, DUD, and QU), the tolerance variation of bore and outer diameter is controlled within each set of NSK bearings.

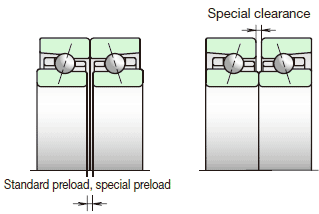

Preload (13)

- EL: Extra light preload

- L: Light preload

- M: Medium preload

- H: Heavy preload

- CP: Special preload

- CA: Special clearance

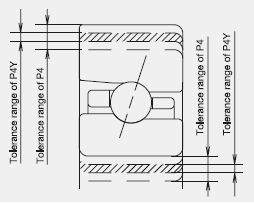

Accuracy (14)

- P2: ISO Class 2

- P4: ISO Class 4

- P5: ISO Class 5

- P3: Special class (dimensional accuracy ISO Class 4, rotation accuracy ISO Class 2)

- P4Y: Sepcial class (dimensional accuracy of bore and outer ring are exclusive for NSK, all others are ISO class 4)

For more details, please refer to Bearing tolerance chart.

Accessories (15)

+Y3: O-ring on bearing outside surface, available for NSKROBUST direct lubricating bearings (E34) only.

Grease brand (16)

Grease typically used in machine tool spindles:

- MTE: MTE grease

- MTS: MTS grease

Grease quantity

- X: 15% of internal space

- K: 20% of internal space

- L: 30% of internal space